How Industry 4.0 Is Transforming Electrical Parts Production

The electrical manufacturing industry is entering a new era. Thanks to Industry 4.0, factories are getting smarter, faster, and more efficient—changing how everything from circuit boards to appliance panels is made. If you’ve ever wondered how your electronics are built or how manufacturers meet growing demand, the answer increasingly lies in automation, data, and connected systems.

Here’s a closer look at how Industry 4.0 is reshaping electrical parts production across the globe.

Table of Contents

- What Is Industry 4.0?

- Challenges Facing Electrical Manufacturers

- Digital Transformation Trends in 2025

- Smart Factories and Automation in Action

- Data, ERP, and Predictive Power

- Real Impacts on Electrical Manufacturing

- Final Thoughts

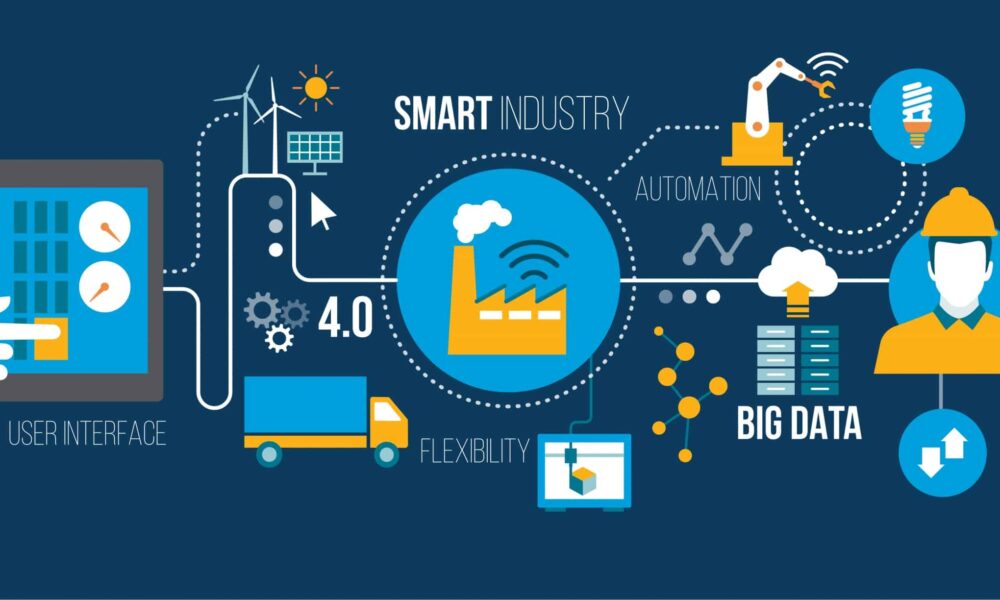

What Is Industry 4.0?

Industry 4.0 refers to the integration of smart technologies like artificial intelligence, the Internet of Things (IoT), robotics, and cloud computing into the manufacturing process. It’s the fourth major revolution in industry—after mechanization, electrification, and early automation.

In electrical manufacturing, this means using data and connectivity to streamline how components are made, tested, and delivered.

Challenges Facing Electrical Manufacturers

Even with advancements, manufacturers face steep hurdles:

- High customization in product lines

- Global supply chain instability

- Quality assurance demands

- Labor shortages in technical roles

- Strict compliance standards

These appliances electrical electronics manufacturing industry challenges pressure factories to do more with less—pushing the shift toward digital tools and smarter workflows.

Digital Transformation Trends in 2025

Several Industry 4.0 trends are accelerating across the electrical components manufacturing company landscape:

- Digital manufacturing in electrical and electronics market operations is replacing outdated legacy systems.

- Advanced ERP for electrical and electronics manufacturing centralizes control across teams.

- Sensors and real-time tracking reduce downtime and enable predictive maintenance.

- Flexible automation adjusts to shifts in demand without requiring full retooling.

These trends align with 2025’s appliances electrical electronics manufacturing industry growth projections, showing strong momentum for companies adopting Industry 4.0 technologies.

Smart Factories and Automation in Action

Today’s “smart factories” are equipped with systems that monitor, learn, and respond without human input. In electrical panel manufacturing or electrical product manufacturing, machines now self-correct errors, sync with inventory platforms, and share performance data.

For example, if a component in an assembly line begins to drift out of spec, the system can automatically pause, alert a technician, or reconfigure upstream steps to minimize waste.

In highly competitive regions like electrical manufacturing Chicago, these changes aren’t futuristic—they’re already happening. This smart automation helps regional factories maintain speed and quality in a crowded market.

Data, ERP, and Predictive Power

Industry 4.0 is fueled by data. Today’s systems capture everything from equipment temperature to energy usage. But collecting data isn’t enough—it must be organized and analyzed.

That’s where ERP systems come in. For an electrical equipment manufacturing company, ERP helps:

- Forecast raw material needs

- Prevent costly downtime

- Optimize worker schedules

- Connect suppliers and logistics in real-time

These systems are especially valuable for manufacturing electrical equipment in fast-paced environments or where see electrical harness manufacturing is involved—where precision and timing are critical.

According to the Department of Energy’s Advanced Manufacturing Office, digital tools like ERP and IoT are essential to maintaining competitiveness in the modern industrial economy, especially in cities like electrical manufacturing Chicago.

Real Impacts on Electrical Manufacturing

The rise of Industry 4.0 has real-world benefits:

- Fewer defects: Smart sensors catch issues instantly

- Faster lead times: Automated systems speed up changeovers

- Lower operating costs: Predictive maintenance reduces downtime

- Better job satisfaction: Workers handle skilled tasks, not repetitive ones

- More flexibility: Lines can adapt to different products without full resets

These gains are visible across the electrical manufacturing industry, especially in companies building smart appliances, electric vehicle components, or industrial systems.

Even international organizations like the International Trade Administration now track U.S. growth zones like electrical manufacturing Chicago as major hubs for high-tech production and advanced electronics.

Final Thoughts

Industry 4.0 is more than a trend—it’s a transformation. For the electrical manufacturing industry, the shift means new jobs, smarter systems, and a future built on precision and speed. Whether it’s ERP systems, connected machines, or real-time analytics, the factory floor is evolving fast.

And for anyone involved in building, buying, or relying on electrical components, it’s worth knowing that behind every product is a factory getting sharper and smarter every day.